Understanding Electromagnetic Shielding Materials

What are Electromagnetic Shielding Materials?

Electromagnetic shielding materials are substances designed to prevent electromagnetic interference (EMI) from affecting sensitive electronic equipment and systems. This interference can distort signals, disrupt operations, and lead to significant failures in functionality. Within this context, electromagnetic shielding materials serve as protective barriers that block or attenuate electromagnetic waves, enabling devices to operate more reliably in environments teeming with electronic noise.

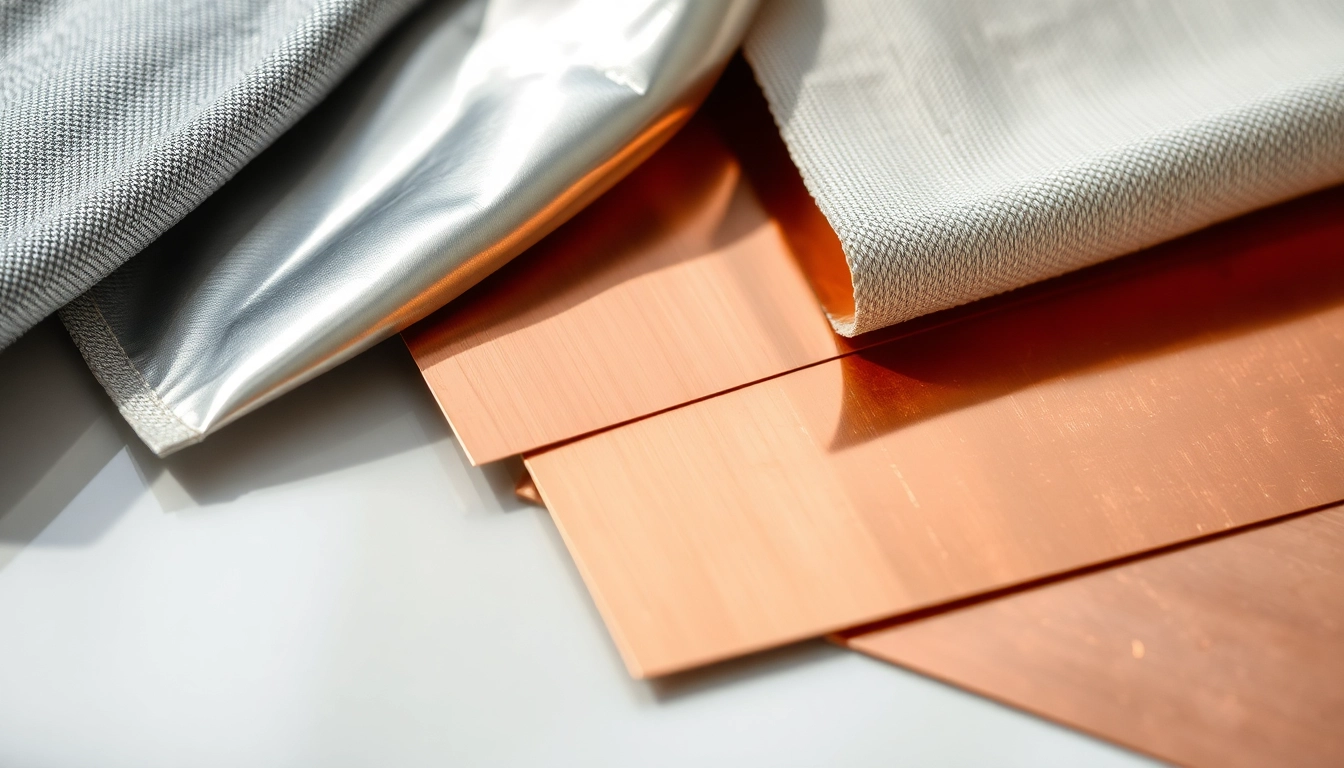

The most common materials for electromagnetic shielding include metals such as copper, aluminum, and steel, as well as newer options like conductive polymers and nanocomposites. These materials can be fabricated in various forms, including thin films, sheets, foams, and specialized coatings, to meet specific shielding requirements. For those seeking comprehensive solutions, electromagnetic shielding materials extend across numerous applications and technologies, adapting to the unique needs of diverse industries.

Importance of Electromagnetic Shielding Materials in Daily Applications

The relevance of electromagnetic shielding materials extends beyond specialized electronic devices to the everyday lives of consumers. They play a critical role in ensuring the functionality of essential equipment, from mobile phones to hospital imaging machines. For instance, in hospitals, electromagnetic shielding helps maintain the integrity of MRI machines by preventing external electromagnetic fields from affecting their operation. In consumer electronics, shielding ensures that devices such as smartphones and laptops operate without interference, and connectivity remains stable.

Moreover, the increasing prevalence of wireless communications and electronic devices in homes and workplaces heightens the need for effective shielding materials, making them an indispensable part of modern living. This demand signifies the critical intersection between technology and its advancements for consumer conveniences and medical necessities alike.

Basic Principles of Electromagnetic Interference (EMI)

Electromagnetic interference occurs when unwanted electromagnetic signals disrupt the functioning of electronic devices. EMI can arise from various sources, including natural phenomena like lightning, or artificial sources such as motors, power lines, and electronic devices themselves. Understanding how EMI operates can greatly assist in selecting appropriate shielding materials.

The fundamental principles behind EMI involve the interaction of electromagnetic fields with conductive materials. When electromagnetic waves encounter conductive boundaries, such as metals, they can be reflected, absorbed, or transmitted. Shielding materials aim to enhance reflection and absorption while minimizing transmission to safeguard sensitive electronics. Comprehensive shield designs often employ multiple layers and varied materials to optimize performance and adaptability to specific frequencies and interference types.

Common Materials Used for EMI Shielding

Metals: Pros and Cons of Common Choices

Metals have been the go-to for EMI shielding, favored for their excellent conductivity and effectiveness in reflecting electromagnetic waves. The most popular metals used in shielding applications include:

- Copper: Known for its superior conductivity, copper provides excellent shielding, especially at high frequencies. It is widely used in telecommunications and electronics.

- Aluminum: Lightweight and cost-effective, aluminum is often chosen for its good conductivity and corrosion resistance, making it a practical option for various applications.

- Steel: While heavier than aluminum, steel offers structural strength alongside effective shielding capabilities, particularly when thermal and mechanical durability is also necessary.

- Nickel: Often used in alloys, nickel provides good shielding performance, particularly against electrical interference.

Despite their advantages, metals also have disadvantages, such as susceptibility to corrosion (particularly for copper) and weight considerations (as with steel). Additionally, the cost of materials can vary significantly depending on availability and market demand, posing budgetary challenges for some applications.

Conductive Polymers: An Emerging Alternative

In recent years, conductive polymers have emerged as popular alternatives to traditional metals for EMI shielding applications. These materials, which can be applied as inks or fabricated into flexible films, offer many benefits:

- Flexibility: Conductive polymers can be manufactured into thin, lightweight forms that can be integrated into a wide range of designs, including wearable technology.

- Cost-Effectiveness: Typically less expensive than metals, conductive polymers can help reduce overall project costs.

- Corrosion Resistance: Unlike metals, conductive polymers do not corrode, contributing to a longer lifespan in many applications.

While still not as conductive as metals, their application in conjunction with other materials can yield effective shielding solutions, especially in consumer electronics and flexible devices. Continued research into enhancing their properties will likely bolster their position in the EMI shielding market.

Nanocomposites: The Future of EMI Shielding

Nanocomposites represent one of the most significant advancements in the field of electromagnetic shielding. By combining materials at the nanoscale, scientists can exploit unique properties to create advanced shielding solutions. These composites often consist of polymers reinforced with conductive nanoparticles like carbon nanotubes or metallic nanoparticles.

The benefits of nanocomposites include:

- Enhanced Performance: Their unique structure allows for improved conductivity and shielding performance without the weight penalties associated with metals.

- Customization: Nanocomposites can be tailored for specific applications, allowing for targeted electromagnetic filtration and attenuation features.

- Reduced Material Usage: As these materials outperform traditional options, they can be used more sparingly, contributing to lower material costs and environmental impact.

This innovative field is garnering significant interest from researchers and industries alike, promising to push the boundaries of what is possible in EMI shielding solutions.

Applications of Electromagnetic Shielding Materials

Healthcare: Protecting Sensitive Equipment

In the healthcare sector, electromagnetic shielding has critical applications for protecting sensitive medical equipment from EMI. Devices such as MRI machines, ultrasound devices, and even infusion pumps require shielding to ensure their accuracy and reliability. For example, even weak electromagnetic interactions can compromise imaging quality in MRI systems, leading to misdiagnoses.

Effective shielding can be achieved through specialized enclosures built from high-performance metals or advanced composites that mitigate electromagnetic interference. Thus, hospitals often rely on expert consultations to assess risks and implement appropriate shielding solutions tailored to their specific environments.

Consumer Electronics: Ensuring Device Reliability

As consumer electronics continue to proliferate, the necessity for effective electromagnetic shielding grows. Devices such as smartphones, laptops, and tablets all require protection from EMI to function correctly and reliably. The miniaturization of components necessitates even greater shielding effectiveness in smaller footprints, compelling manufacturers to seek out advanced materials.

Moreover, the clamor for wireless technology also aligns with the demand for stronger electromagnetic shielding. With numerous signals operating simultaneously, robust shielding ensures that a device maintains connection quality while minimizing interference from adjacent devices.

Industrial Uses: Mitigating RF Interference

Industries often experience significant electromagnetic noise disruptions due to heavy machinery and electrical systems. Consequently, manufacturers increasingly deploy shielding materials within their operations to minimize this interference.

In manufacturing, individual equipment may be shielded to prevent interference with sensitive electronic controls. Shielded enclosures and panels can protect electronic equipment from high electromagnetic fields produced by industrial machinery. In this manner, manufacturers can ensure optimal performance while safeguarding both productivity and worker safety.

Choosing the Right Electromagnetic Shielding Material

Factors to Consider for Effective Shielding

Selecting the appropriate electromagnetic shielding material necessitates consideration of various factors, such as:

- Frequency Range: Different materials exhibit varying efficacy at different frequencies, necessitating an understanding of the electromagnetic spectrums that need to be shielded.

- Environmental Conditions: Consideration of exposure to moisture, temperature, and corrosive elements enhances the selection process.

- Cost Constraints: Balancing performance against budget limits is essential, with options ranging from cost-effective conductive polymers to high-performance metals.

Comparative Analysis of Costs and Benefits

When analyzing costs and benefits, it is imperative to look beyond initial material prices. Factors such as performance longevity, maintenance costs, and potential losses due to EMI failures should be accounted for. While leading metals like copper offer unmatched shielding capabilities, they may also present higher upfront costs. On the other hand, emerging materials like conductive polymers may be better suited for sensitive applications where flexibility and cost-effectiveness can achieve a comparable outcome.

Case Studies: Successful Applications of Shielding Materials

Numerous industries provide compelling case studies illustrating successful deployment of electromagnetic shielding materials. One such example is found in the telecommunications sector. A major mobile device manufacturer faced continuous signal interference preventing optimal performance of a new product. By implementing advanced nanocomposite materials, engineers achieved superior shielding, which helped the device reach market readiness without delays.

Additionally, research done at prominent hospitals demonstrated that applying specialized shielding enclosures to MRI machines effectively mitigated external EMI, leading to more accurate and reliable patient imaging. These case studies provide practical insights into how the right materials can resolve significant operational challenges across diverse fields.

Future Trends in Electromagnetic Shielding Materials

Innovative Research and Developments

Research in electromagnetic shielding materials continues to evolve, with ongoing developments focused on improving material properties, such as conductivity, flexibility, and weight. Innovations like graphene and other two-dimensional materials show great promise, offering exceptional electrical and thermal conductivity while remaining lightweight.

Moreover, advancements in manufacturing techniques, such as 3D printing, are reshaping how shielding materials are produced. These new methods allow for greater customization, enabling manufacturers to develop solutions tailored to specific shielding needs efficiently.

Predictions for Market Trends and Demand

As the demand for wireless technology and electronic devices surges, the electromagnetic shielding materials market is forecasted to grow exponentially. The increasing need for high-speed wireless connections and the internet of things (IoT) will exacerbate electromagnetic interference, compelling industries to prioritize sourcing effective shielding solutions.

Sustainability Considerations in EMI Shielding

In a world increasingly focused on environmental sustainability, the incorporation of eco-friendly materials into electromagnetic shielding practices remains an emerging trend. Manufacturers are exploring the possibilities of recyclable and renewable materials to mitigate environmental impacts while maintaining performance standards.

Additionally, the adoption of sustainable practices within the industry will influence customer preferences and regulatory standards. As manufacturers seek to balance performance against ecological impacts, sustainability in material selection will become a key driver of innovation.

Leave a Reply