Understanding Thermal Management Materials

What Are Thermal Management Materials?

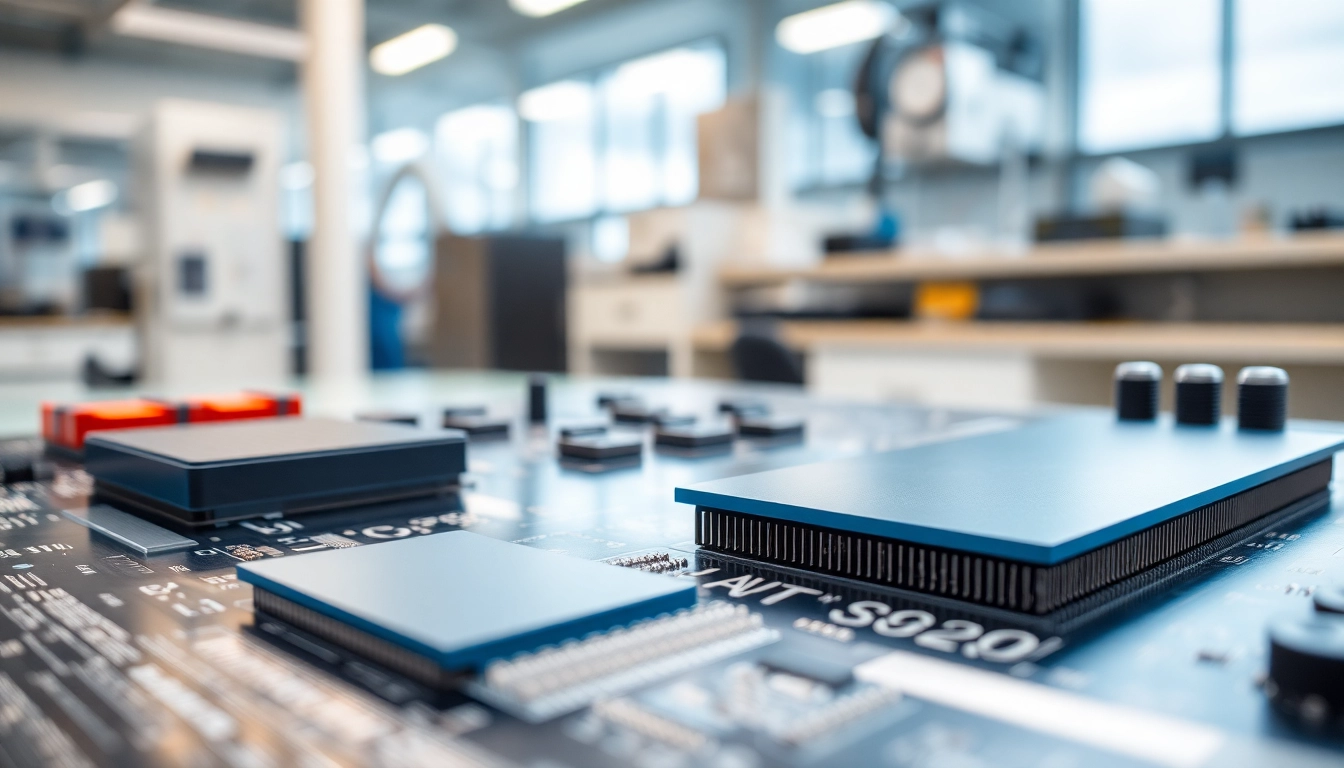

Thermal management materials are a diverse group of products specifically designed to effectively manage and dissipate heat generated during the operation of electronic devices. These materials play a crucial role in a variety of applications by ensuring that devices operate efficiently and safely, avoiding overheating that could lead to failures or damage. Thermal management is essential in environments where heat generation is a concern, such as in consumer electronics, automotive systems, and high-performance computing.

Typically, these materials form a thermal interface between components, facilitating heat transfer to maintain an optimal operating temperature. For those seeking high-quality thermal management materials, options include thermal pads, gels, and adhesives, each designed for specific conditions and requirements.

Importance in Electronic Applications

The significance of thermal management materials cannot be overstated, especially in today’s electronics-heavy world, where devices are becoming more powerful and compact. The increased density of electronic components generates substantial heat, which can significantly reduce the lifespan and functionality of the devices if not managed correctly.

Proper thermal management ensures the efficiency of the device and preserves its integrity over time. By maintaining temperatures within specified limits, manufacturers can enhance performance, promote reliability, and improve user safety. Moreover, effective thermal management contributes to enhanced system performance and energy efficiency, crucial factors in competitive markets.

Types of Thermal Management Materials

There are several categories of thermal management materials, each serving unique purposes based on application requirements. The most common types include:

- Thermal Interface Materials (TIMs): These are critical components that facilitate heat transfer between heat-generating and heat-dissipating surfaces. They comprise thermal pads, thermal greases, and phase-change materials (PCM).

- Thermal Pads: Often used to fill air gaps, thermal pads can improve the conduction of heat between surfaces. They come in various thicknesses and thermal conductivities to meet specific design needs.

- Thermal Adhesives: These provide both thermal conductivity and bonding capabilities, ensuring components adhere well while managing heat.

- Gap Fillers: Designed to fill large air gaps between components, gap fillers aid in efficient heat transfer without structural support.

- Thermal Gels: These soft, malleable materials offer excellent thermal conductivity and can be molded into complex shapes to enhance heat dissipation.

Key Features and Benefits

Efficiency in Heat Dissipation

The primary role of thermal management materials is to enhance the efficiency of heat dissipation in electronic systems. Materials engineered with high thermal conductivity allow heat to flow away from critical components quickly, preventing thermal build-up that could lead to overheating. For example, thermal pads with a high-performance rating can achieve thermal conductivity values over 10 W/mK, providing superior heat dissipation in compact spaces.

Compatibility with Various Systems

An essential advantage of modern thermal management materials is their compatibility with a wide range of systems and devices. The materials can be customized based on the specific thermal requirements and environmental conditions they will encounter, making them suitable for everything from smartphones to electric vehicles. Their adaptable nature allows for integration into existing designs without substantial modifications.

Durability and Reliability

Many thermal management materials are engineered to withstand harsh conditions, including extreme temperatures and mechanical stress. The durability of these materials ensures long-term performance and reliability, reducing the frequency of maintenance or replacement in critical applications. For instance, silicone-based thermal compounds not only offer excellent thermal conductivity but also retain their properties across wide temperature ranges, making them ideal for high-performance applications.

Common Applications of Thermal Management Materials

Consumer Electronics

The consumer electronics market extensively utilizes thermal management materials to ensure optimal functioning and longevity of devices like smartphones, laptops, and tablets. For example, thermal pads and conductive adhesives are often used to manage heat in CPU and GPU modules, allowing for sustained performance during intensive tasks such as gaming or video editing.

Automotive Applications

In the automotive industry, efficient thermal management is critical for maintaining performance and safety. With the rise of electric vehicles (EVs), managing battery temperatures is more relevant than ever. Thermal interface materials help maintain optimal battery temperature, enhancing safety and extending battery life. Additionally, thermal management solutions in internal combustion engines help prevent overheating, improving engine efficiency and prolonging operational lifespan.

Industrial Uses

Industries such as aerospace, telecommunications, and manufacturing employ thermal management materials to enhance equipment performance and reliability. Heat exchangers utilize thermal pads and gels to manage the heat produced in their systems, which is crucial for maintaining operational efficiency and ensuring compliance with safety standards.

Best Practices for Implementation

Selecting the Right Material

Choosing suitable thermal management materials involves understanding the specific requirements of the application, including thermal conductivity needs, operating temperatures, and compatibility with other materials. Manufacturers should consider factors such as mechanical properties, thermal performance, ease of application, and longevity. Engaging with a knowledgeable supplier can provide valuable insights into selecting the ideal material for specific applications.

Application Techniques

Proper application techniques are vital for the efficiency of thermal management materials. Techniques can include manual application, dispensing, or even automated processes, depending on the complexity and scale of production. Ensuring even coverage without air pockets is critical, as even minor imperfections can negatively impact thermal performance. Following manufacturer guidelines on application thickness and curing processes will also ensure optimal performance.

Maintenance and Monitoring

Regular maintenance and monitoring are essential to ensure that thermal management solutions continue to perform effectively. Factors such as environmental conditions or aging can affect material properties over time. It is advisable to have a preventive maintenance schedule that includes inspection of thermal interfaces and assessments of heat dissipation efficiency, all crucial for ensuring longevity and reliability in critical systems.

Future Trends in Thermal Management Solutions

Advancements in Materials Technology

The future of thermal management materials is marked by continuous advancements in material science. Innovations in nanotechnology are leading to the development of materials that exhibit significantly improved thermal conductivity and other desirable properties. Additionally, hybrid materials that combine multiple functionalities—like conductivity, insulation, and structural support—are expected to emerge, providing comprehensive solutions to complex thermal challenges.

Market Predictions

The demand for thermal management materials is anticipated to grow driven by the increasing miniaturization of electronic devices and the expansion of electric vehicle markets. As technology continues to evolve, manufacturers will seek increasingly effective solutions to manage heat more effectively. Reports indicate that the global thermal management materials market is poised for robust growth, reflecting wider adoption across various sectors.

Environmental Considerations

Sustainability is becoming an increasingly critical aspect of material selection. The development of eco-friendly thermal management materials with low environmental impact will be a key focus for manufacturers and consumers alike. Biodegradable materials and those derived from sustainable sources are expected to gain traction, aligning with global sustainability efforts and regulations.

Leave a Reply